2024-02-06 Closed Barrel SectionsThe most common barrel section design is, of course, the closed barrel section (Fig. 2). This barrel section fully encases the polymer melt on all four sides of the extruder with only a figure 8 opening through the center for the screws.

Read More

2024-02-06 The design of the twin-screw extruder provides an advantage over other plastic processes. Full flexibility gives the process engineer the ability to configure the extruder to optimize the process and produce the best properties attainable.

Read More

2023-12-21 Barrel MaintenanceProper maintenance of the twin screw extruder barrel is critical for performance and safety. The barrel should be kept clean and free of material buildup through regular cleaning procedures.Cleaning ProceduresAfter each job, thoroughly clean the barrel using purge compounds designe

Read More

2023-12-20 In the process of compounding extrusion production, various chemical additives are often added to improve the overall performance of the products. However, this practice can lead to increased wear and corrosion of the twin-screw extruder screw and barrel. This not only results in a significant waste

Read More

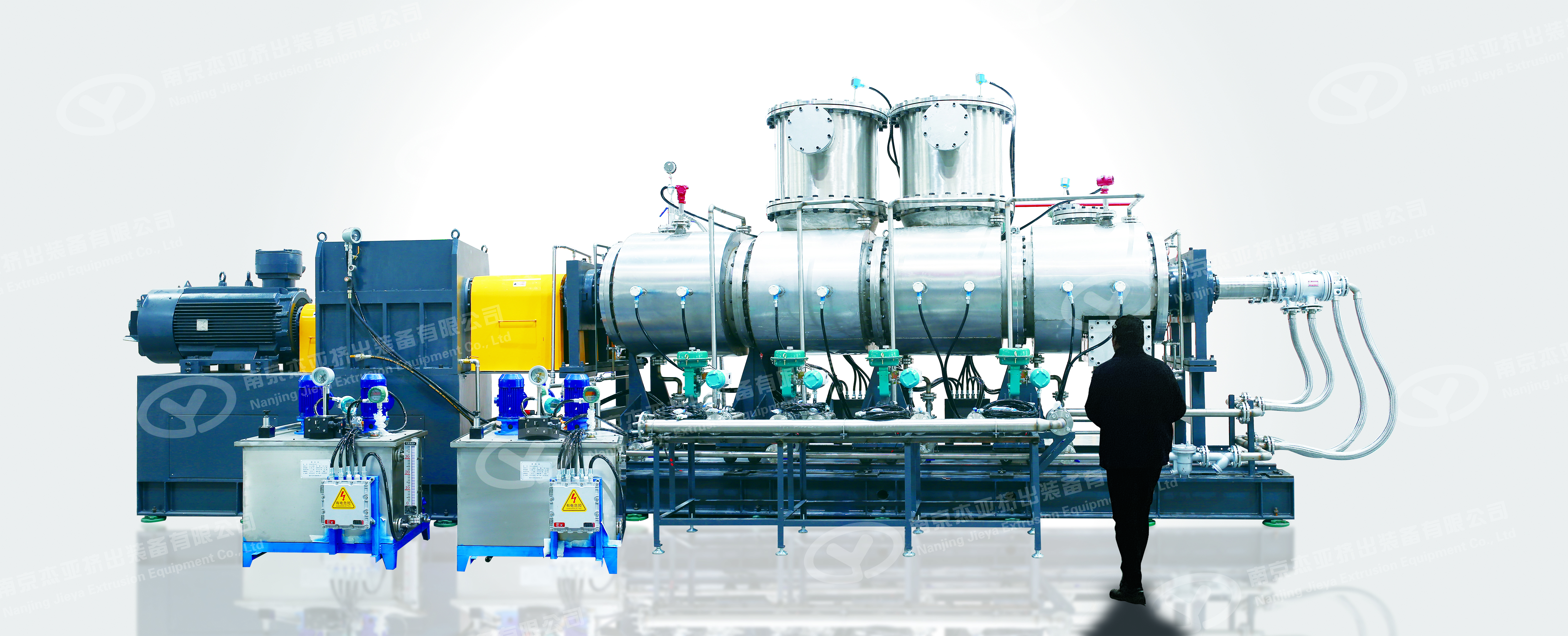

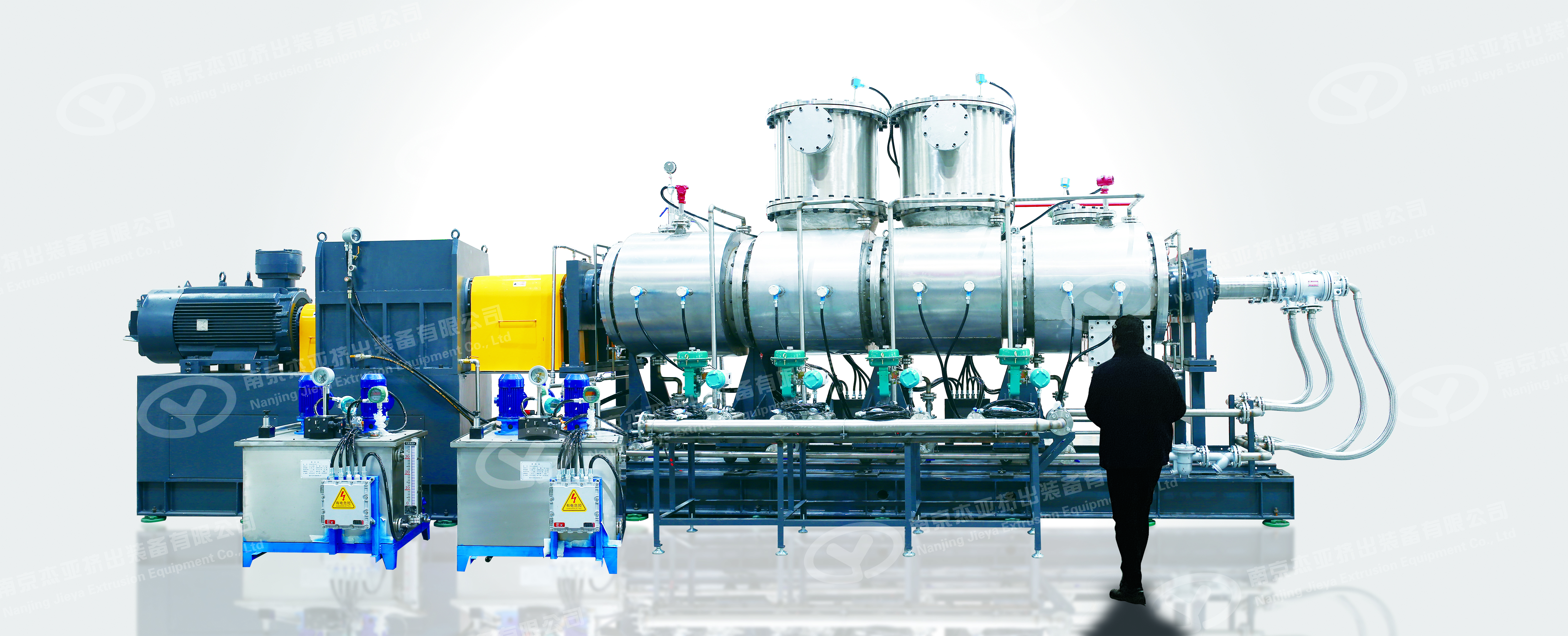

2023-12-08 A devolatilization extruder is a specialized type of extrusion equipment used in the processing of polymers to remove volatile components from the material. Volatile components can include solvents, monomers, or other substances that are present in the polymer melt. The devolatilization process is c

Read More